A Closer Look: F.P. Journe Répétition Souveraine with Smoked Sapphire Dial

Reviews

A Closer Look: F.P. Journe Répétition Souveraine with Smoked Sapphire Dial

Few watchmakers today demonstrate the breadth of mechanical curiosity seen in the work of François-Paul Journe. Much has already been written about him, but I’ve always found the contrast between Journe and George Daniels to be quite interesting, even though both carry forward the legacy of 18th century horology. Daniels pursued watchmaking with a staunch preoccupation with precision and purpose. While both shared a certain mechanical elegance and took the best ideas from the past and improved on them, Journe, like Breguet, has a restless ingenuity that extends far beyond chronometry into various other branches of horology. It encompasses not only the more unusual and artistic interpretations of time, such as the Vagabondage series and the FFC, but also extends to quartz technology. Complications have also held an equally central place in his work. In fact, they are the most numerous, including and up to, the Astronomic Souveraine.

Each offers a window into his distinctive, and at times very idiosyncratic vision. They tend to have a sense of exploration about them and often feel like very personal inquiries, such that without understanding their conceptual basis, it can be difficult to fully grasp his genius or intent. Among them, the Répétition Souveraine deserves particular attention. They all do, undoubtedly, but the Répétition Souveraine stands out as a highly inventive reimagining on the half-quarter repeaters of the 18th century such as those of Breguet. In every aspect, it differs dramatically from any other minute repeater created by any other watchmaker or brand in modern times. Apart from the snails, little of the mechanism is recognisable within the context of minute repeaters as we know them today.

Minute repeaters are not so much built as they are coaxed into being, and when even the most capable watchmakers approach them, they tend to do so with a certain deference. The risks of invention – or reinvention – are high, and the margin for error both in the mechanics of the strike and the acoustics of sound is painfully narrow. Thus, Journe’s approach is both fascinating and singular.

The Répétition Souveraine was launched in 2008, just two years after Journe completed his Sonnerie Souveraine. While it adopted the same principle of flat gongs mounted beneath the dial for a clearer, louder sound when worn on the wrist, everything else about the striking mechanism is entirely different from the Sonnerie Souveraine. It was constructed as a slimmer, mechanically streamlined minute repeater where each hammer is activated with a single pallet working with a single set of teeth.

The watch measures just 8.5mm high and was originally launched with a solid silver guilloche dial. It is one of the few F.P. Journe watches outside of the 2015 38mm steel set to be made in stainless steel, for better acoustics. Later, a second model was introduced as part of the Black Label range. Additionally, since 2020, a third model with a smoked sapphire dial is offered upon request, and it is inarguably the most beautiful of the three.

Ultra-Thin Strike Works

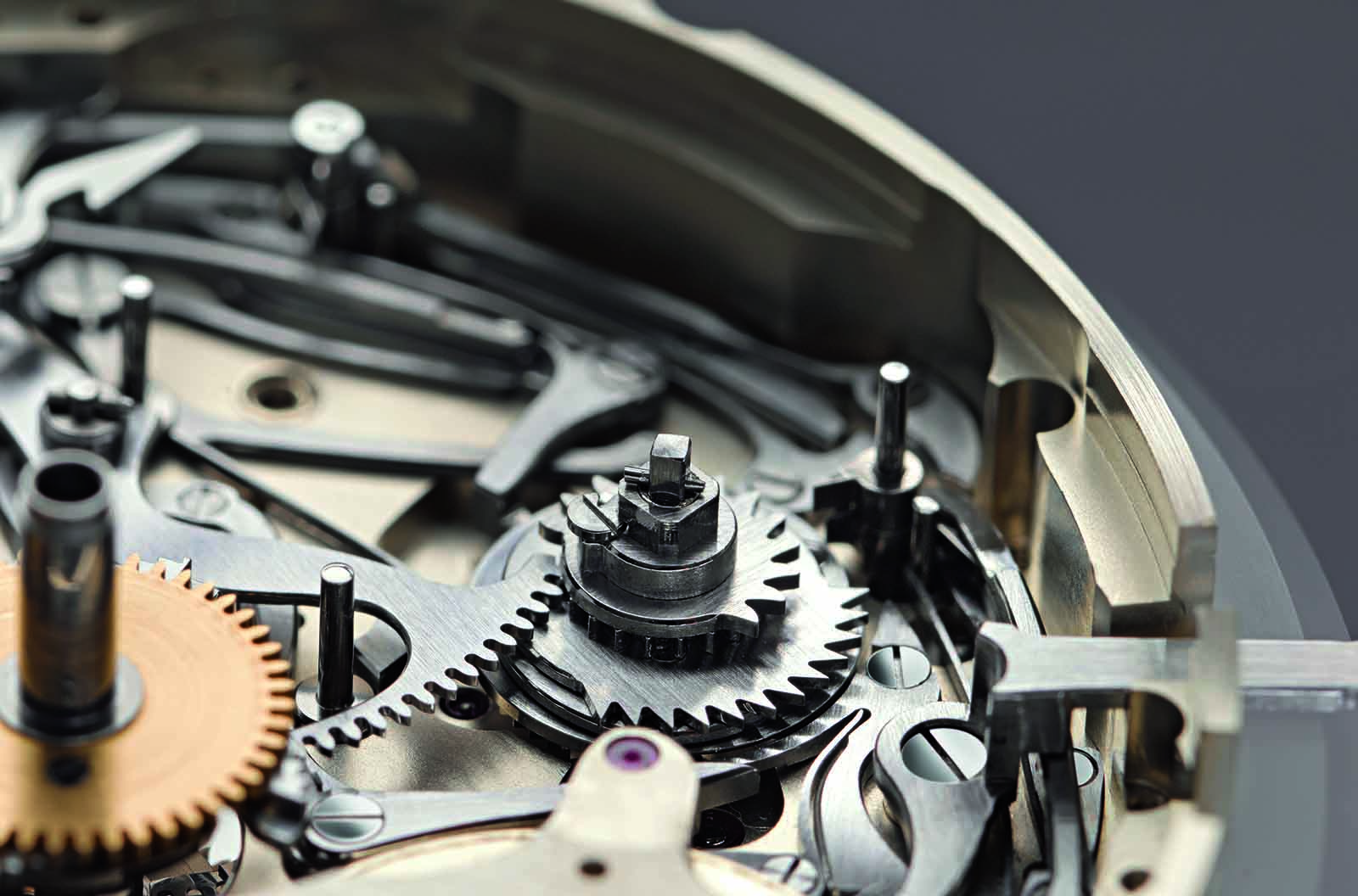

The unusual strike works is entirely visible beneath the smoked sapphire dial. At 12 o’clock is a component not typically found in a modern minute repeater – a striking wheel, sometimes referred to as a count wheel. In more recent years, the Chopard Full Strike is the only one (that I know of) which uses a striking wheel. In fact, it uses three striking wheels that are arranged co-axially – one for the hours, quarters and minutes – and the goal was to save horizontal rather than vertical space.

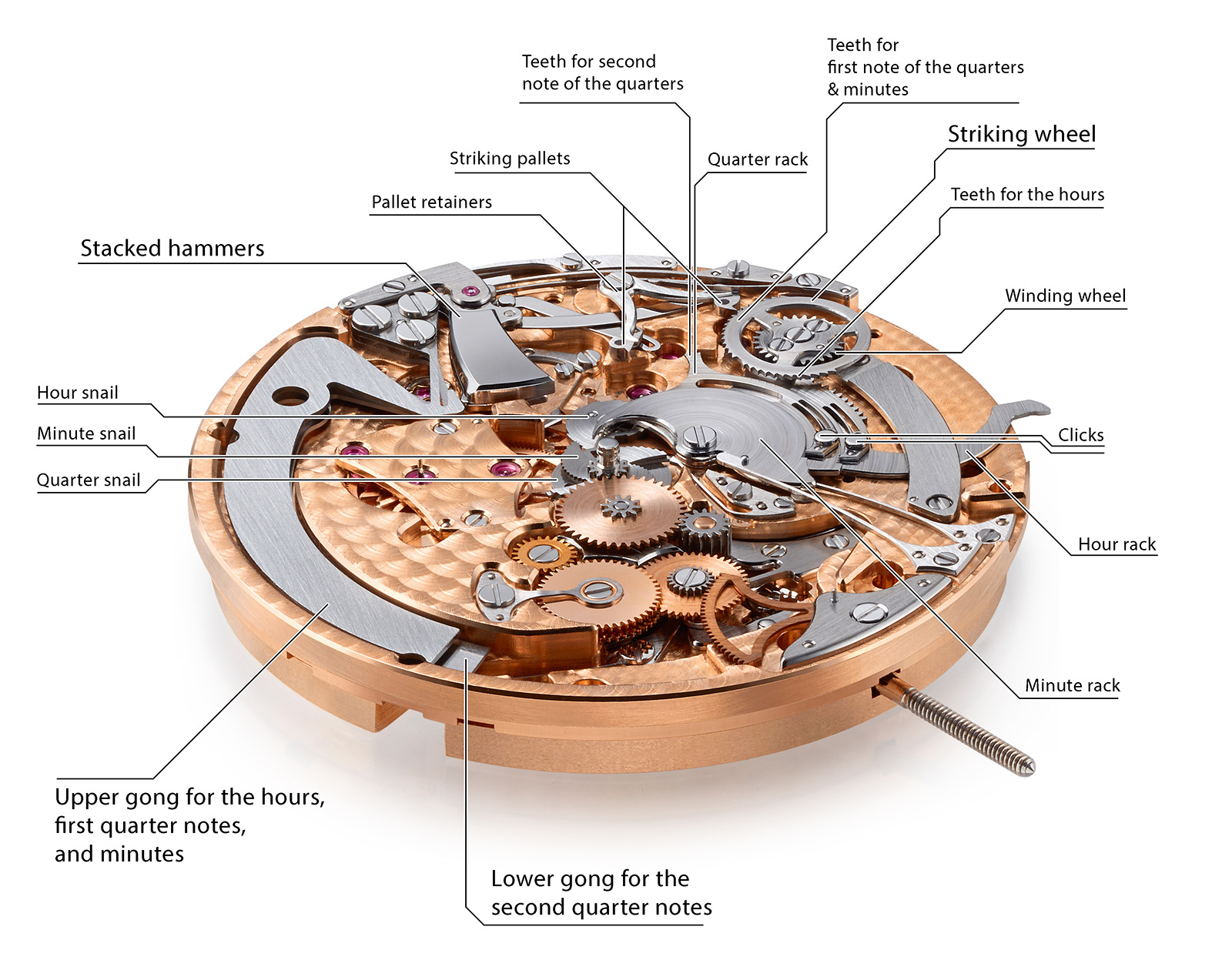

At around 12 o’clock, there is a striking wheel with two sets of ratchet teeth – one used to strike the hours and other to strike the first note of the quarters and minutes. The racks themselves do not interact with the pallets (Image: Revolution ©)

In Journe’s design, this striking wheel has two distinct sets of ratchet teeth – one used to strike the hours and other to strike the first note of the quarters and minutes. There is a gap in between the two sets of teeth to encode the pause. This means that unlike a normal minute repeater, the hours and minutes are struck using the same hammer on the same gong, and indeed, it is this striking wheel that contacts the striking pallets rather than the racks themselves.

This striking wheel was introduced primarily to reduce the vertical height and complexity of a traditional minute repeater. In a standard minute repeater, each hammer is actuated by two striking pallets. The first hammer is actuated first by a pallet engaged by the hour rack, then by a second pallet engaged by the quarter rack to deliver the first note of each quarter. The second hammer is similarly actuated by one pallet operated by the quarter rack for the second note of each quarter, and another operated by the minute rack for the final minute strikes. Each of these pallets is mounted on its own pivot but arranged in a vertical stack, with the hammers reset by springs and resting against all the pallets via arms or levers. This stacked arrangement contributes significantly to the height of the mechanism.

Journe’s design uses only two pallets, one for each hammer. The hammers in the Répétition Souveraine are arranged in a vertical stack, as are the gongs, with one placed directly above the other. The upper hammer is hinged to an arm that pivots around a fixed pin. It strikes the visible upper gong when released by its corresponding striking pallet. The lower hammer is similarly mounted to a separate arm that pivots around its own fixed pin. It strikes a second gong located beneath the first.

Journe’s design uses only two pallets, one for each hammer, instead of the usual four (Image: Revolution ©)

The upper hammer is activated by the striking wheel while the lower hammer is triggered by the quarter rack to strike the second note for the quarters. Both the striking wheel and the use of a single pallet for each hammer recalls Breguet’s efforts to achieve compactness in his repeaters. Breguet used a single hammer and pallet in his half-quarter repeater. It strikes single notes for the hours, followed by double notes for the quarters and single note for the following half-quarter if there is, all using the same hammer. His design was itself adapted from the repeaters of the English watchmaker Matthew Stogden.

Right beneath the striking wheel in Journe’s design is a winding wheel that is fixed to the arbour of the repeater barrel, allowing it to be wound directly by the hour rack when the repeater slide is cocked. In a traditional minute repeater, the barrel has four components squared to its arbour: (1) a rack pinion that allows the barrel to be wound, (2) a circular hour rack itself, (3) a finger that drives (4) a quarter driving pinion, which in turn drives the quarter rack. This stacked construction adds considerable height. In Journe’s repeater, the hour rack is no longer squared to the barrel arbour, which eliminates the need for (3) and (4).

This example shows the number of components attached to the repeater barrel arbour in a traditional minute repeater. From bottom to top: the hour rack, winding rack pinion, quarter driving pinion and finger. On the left of this assembly is the winding rack which winds the barrel via the winding pinion

The three racks – hours, quarters and minutes – are superposed on a separate pivot axis. Since the racks are not required to carry individual sets of ratchet teeth to engage separate striking pallets, nor to engage stacked pallets as in traditional repeaters, there is no need for vertical spacing or play between them. This compact layering is also made possible by the clever use of clicks that mechanically link the racks in sequence, allowing them to function as a single kinematic chain without interfering with one another.

The hour rack is the only one directly wound by the repeater slide. When the repeater is cocked, the hour rack pivots clockwise against the hour snail and simultaneously winds the repeater barrel. As it does so, the striking wheel fixed to the barrel arbour rotates clockwise along with it, but this direction of motion has no effect on the striking mechanism since the ratchet teeth slide past the striking pallet without lifting it. Attached to the hour rack is a click which is a small, pivoting linkage held by two pins and spring-loaded by a finger spring cut from the hour rack itself.

This click travels along a toothed arc on the quarter rack, engaging it only during the return stroke. Once the repeater slide is released, the mainspring drives the striking wheel counterclockwise, and the hour rack is pulled back in the opposite direction. Now the ratchet teeth on the striking wheel lift and release the first striking pallet, which in turn raises and drops the hammer to strike the hour gong.

The engagement between pallets and teeth is controlled by a two-pronged lever that keeps both pallets under spring tension. This lever consists of two arms, each resting against the upper planar surface of one of the pallets. The lever pivots about a fixed pin and is kept in contact with the pallets by a return spring. As a result, the pallets are always held in position to be acted upon by their respective sets of ratchet teeth throughout the return strokes.

A two-pronged lever at 11 o’clock keeps both pallets under spring tension to be acted upon by the strike wheel or the quarter rack (Image: Revolution ©)

As the hour rack completes its return, the click of the hour rack reaches the end stop on the arc of the quarter rack and begins to push the quarter rack. The teeth on the striking wheel continue to be pulled past the first pallet, delivering the first note of the quarter. Simultaneously, the ratchet teeth on the quarter rack engage the second pallet, delivering the second note of each quarter.

The quarter rack has its own click, identically constructed and spring-loaded via a finger spring cut from its arm. This click engages a toothed arc on the minute rack, again only during the return stroke. When the quarter strikes are complete, this second click reaches the end of the minute rack’s arc and pushes the minute rack through its motion to initiate the minute strikes.

The gongs are designed as flat, curved blades rather than the traditional round wire loops. This structural departure allows them to occupy significantly less vertical space. Each gong is cut from a metal sheet and is shaped to follow roughly half the periphery of the movement. One end of the blade features a gradually narrowing waist, which serves to reduce stiffness, thereby lowering the natural frequency of that section and to create a tuning zone that can be manually adjusted e.g. filed during assembly for fine acoustic calibration.

The hammers in the Répétition Souveraine are arranged in a stack, as are the gongs, with one placed directly above the other and connected to their respective pallets (Image: Revolution ©)

Crucially, the hammer strikes the edge of the gong in-plane, rather than from above or below. This results in flexural vibration along the plane of the blade, where the stiffness is greatest. After each strike, a dedicated return spring immediately pulls the hammer back to its resting position, preventing any damping or interference with the sustained vibration of the gong.

To get a better idea of the action and interaction of the parts, watch the video below:

Calibre 1408

The Calibre 1408 shares the same base architecture as the Calibre 1304 found in the Chronomètre Souverain. While the 1304 measures just 4mm thick, the 1408 adds only half a millimetre. It is equipped with double barrels arranged in parallel that deliver a power reserve of 56 hours. The power reserve mechanism is similarly compact. Under the sapphire dial, the output train is visible on the lower right quadrant of the movement. It drives a rack which in turn carries the power reserve indicator hand. There is a curious tensioner on one of the intermediate output wheels to ensure it remains in contact with an underlying wheel. Why, I do not know, but it appears to not be using a traditional differential.

The repeater train is located under the bridge at 12 o’clock with the centrifugal governor mounted above it (Image: Revolution ©)

Like the Calibre 1304, the movement was designed such that the escape wheel appears to be mysteriously disconnected from the gear train. While the center wheel is visible between the barrels, the rest of the going train before the escape wheel are hidden beneath the base plate. The Calibre 1408 has a smaller balance cock to make room for the strike train. The train is supported by an additional bridge, with the centrifugal governor mounted on top to control the unwinding rate of the repeater barrel.

The flying governor has a housing that echoes the design of Journe’s signature screwed sub-dial frames. (Image: Revolution ©)

The watch is undeniably beautiful, but more than that, it embodies something extremely rare – a minute repeater that works, sounds and thinks differently. It is neither reverential nor iconoclastic but somewhat investigative.

It may no longer be the slimmest minute repeater on the market, nor is it the loudest or most resonant, but the solutions are intriguing and representative of a watchmaker’s inquiry into how far one can simplify without subtracting. It is a continuation of a lineage that produced Breguet but filtered through a singular mind still asking old questions in search of new answers.

Tech Specs

F.P. Journe Répétition Souveraine with Smoked Sapphire Dial

Reference: Ref. RM

Movement: Manual-winding 1408; 56-hour power reserve; 3Hz or 21,600vph

Functions: Hours, minutes and small seconds; power reserve indicator; minute repeater

Case: 40mm × 8.5mm; Stainless steel

Dial: Smoked sapphire with ivory numerals with blued steel hands

Strap: Leather strap

Availability: Limited production

Price: CHF 280,000 (excl. taxes)

F.P. Journe