The Watchmaker’s Journey: Balancing Tradition, Technology, and Community

Opinion

The Watchmaker’s Journey: Balancing Tradition, Technology, and Community

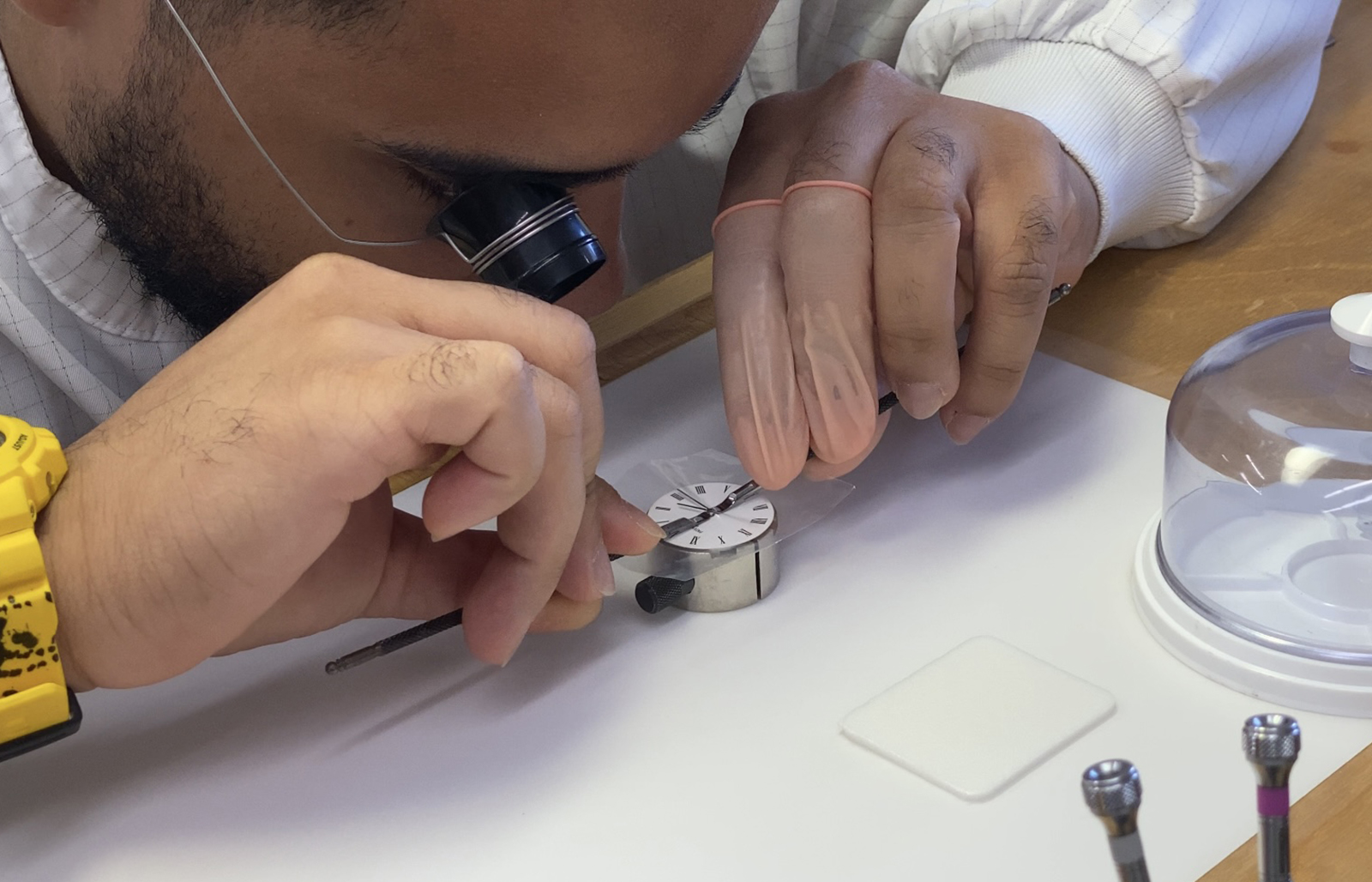

As a craft that is more than 400 years old, horology in 2024 is still an art form that demands precision, patience, and a deep understanding of mechanical intricacies. Above all else, however, this is a craft that requires a community — watchmakers, clock makers, artisans and technicians teaching and learning from each other. There are numerous stories detailing how watchmakers must train under the watchful eye of our mentor, how we must train our eyes, hands, and minds to be able to perform these delicate operations and/or repairs while keeping the highest standards of cleanliness, aesthetic presentation, technical specificities and, of course, accurate timekeeping. This is because that is what’s necessary for the new watchmaker, fresh out of school, to become proficient and independent in their work.

Throughout the last few hundred years this beloved craft of ours has not lowered its standards. In fact, the standards have only gone higher. Watchmakers are no longer only concerned with the proper function of a mechanical movement inside a beautiful case — water resistance is now a requirement, which adds another layer of complexity to the repair process. Cleanliness standards are higher than ever as each timepiece is checked under high magnification and even under a microscope.

The final challenge — this one being rather new and still developing — is social media. With the availability of macro lenses that you can easily attach to your phone, there are plenty of watch enthusiasts who scrutinize each wristwatch they purchase (new or pre-owned), making note and highlighting beautiful fine finishing, but also any manufacturing errors, pieces of dust, and unclean work. The modern watchmaker must think about this when working. I often tell myself “work as if this watch will be posted on Instagram by one of those accounts”.

If we want to be successful and work at a level of performance that is hardly seen anywhere else, we need to have not just a good education from a watchmaking school, but a great community of watchmakers that can support us and teach us the best way to accomplish our horological goals. Connecting and sharing with other watchmakers, independent and otherwise, enriches our knowledge — and yes, our lives too. This is not always obvious to us as this is an inherently lonely craft. Watchmakers spend several hours each day at the bench quietly working.

Watchmaking school and careers

After graduating from watchmaking school, various career paths open up, such as becoming a watchmaker, estimator, polisher, or assembly line technician. Many graduates start their careers working for major brands, often in after-sales services. While specialized roles such as wheel cutting or pinion polishing are crucial, as these skills are required for both the production of new watches and the restoration of older timepieces, they may not always be widely advertised and could open up internally, particularly when experienced professionals retire. Interestingly, these specialized positions don’t always require a formal watchmaking degree.

For those who aspire to work on complicated timepieces, the journey is highly personal and demanding. It requires meticulous training of both dexterity and eyesight to handle and adjust these intricate mechanisms. The path to working on such pieces can take several years — with 3-4 years of dedicated effort being considered quite fast — and even then, not everyone reaches this level. Success in this area depends heavily on one’s skillset, experience, and deep understanding of the design DNA of different brands.

My love for watches has always been a constant in my life. After spending six years in the United States Marine Corps, where I relied on my beloved and dependable Casio G-Shock, I felt a strong pull to delve deeper into the world of timepieces, both quartz-powered and mechanical. Once I completed my military service, I began my journey into the watch industry, starting with Skagen Denmark, and later moving on to Bloomingdale’s iconic 59th Street location. There, while I was not working on watches, I found myself up close and personal with brands from TAG Heuer to Cartier, which only fueled my passion further.

In 2017, by chance, I discovered that Patek Philippe was running their own Horology program right in the heart of New York City at Rockefeller Center. My curiosity and passion led me to apply. After a rigorous three-month interview and testing process, I was thrilled to receive the call that I had been selected as one of just six students to join their upcoming class.

Fast-forward through two years of intense schooling and five more years of dedicated learning, practice, skill-building, and immersion in the rich history of watchmaking, I found myself at a crossroads. Working for a well-established brand had provided me with a structured environment where I could develop my skills under the guidance of experienced professionals. The resources available, from specialized tools to formal training, allowed for steady progression in my craft. However, as I reflected on my journey, I realized that my growth and development were often dictated by the brand’s objectives, limiting my exposure to other aspects of watchmaking that I longed to explore.

In March of this year, I decided to take a bold step and go independent. This decision opened up a world of new opportunities but also presented significant challenges. On one hand, I now had the freedom to explore every facet of watchmaking that intrigued me, to set my own high standards of quality, and to cultivate a unique identity within the industry. This autonomy is incredibly fulfilling, especially for someone with a strong vision and a desire to innovate.

However, with this newfound freedom came the responsibility of managing all aspects of the business. I had to excel not only as a watchmaker but also in handling the administrative, marketing, and financial sides of running a workshop. The safety net of working for a big brand was gone; my success now depended entirely on my ability to attract clients, deliver exceptional work, and build a reputation from the ground up.

Additionally, I took on the challenge of creating a space for the watchmaking community — a place where professionals could come together to exchange ideas, advice, and inspiration. While this adds another layer of complexity to my work, it’s a fulfilling endeavor that helps foster collaboration and growth among watchmakers.

In essence, the transition from working for a big brand to going independent has been a shift from a structured, supportive environment to one of total responsibility and creative freedom. It requires not only mastery of my craft but also entrepreneurial skills and the ability to build a brand that reflects my personal values and vision.

The Influence of Technology

While traditional watchmaking remains highly valued, technology has significantly influenced the field. Previously hand-made components are now largely machine-made and finished. Only the most intricate of details are done by hand. Manufacturing, finishing, assembly, and oiling are all done largely by machine across most brands. So how does the traditional watchmaker fit in with all of the new technology eliminating the need for work done by hand in most areas?

The modern watchmaker must think outside the box and step out of their comfort zone to supplement their learning. Leveraging blogs, Facebook groups, YouTube, Reddit, and friends to learn the skills and techniques that would otherwise be out of reach for them.

Thanks to the valuable contributions of watchmaking content creators, such as Wristwatch Revival, Long Island Watch, and others, a new watchmaker fresh out of school can supplement their learning with these valuable resources in lieu of a mentor. There are different blogs, Discord groups and sub-reddits dedicated to sharing information about watch repair. Some of them very useful, others are more of a soapbox for watchmakers to vent and rant (we all need some venting and there’s not many people who will understand us) and excitingly, with the development of 3D printers, watchmakers can now 3D-print their own tools, movement holders and other useful equipment that would otherwise not be available for sale.

Social media plays a big role in this equation, as it connects watchmakers from all over the world and we are able to learn from each other by watching the content that we share, asking questions, recommending trusted craftsmen to help each other, and more. Therefore, community is the key to success in this era. A watchmaker can either go at it alone and learn by trial and error or tap into the power of social networking to solve horological puzzles.

Watch Repairing: An Essential yet Undervalued Art

The global market for watches remains robust, with significant demand for both luxury and everyday timepieces. Luxury watchmakers, often steeped in history and tradition, continue to thrive, catering to a clientele that values exclusivity and heritage. On the other end, affordable and fashionable watches reach a broad audience, often leveraging social media and online platforms for marketing and sales. As the luxury watch industry continues to flourish, the demand for high-quality repair services is on the rise.

Despite its critical importance, watch repairing does not always receive the recognition it deserves, as the focus often remains on the glamorous aspects of watchmaking, such as new inventions and innovative designs. As such, there is a noticeable shortage of qualified labor, posing a significant challenge for both consumers and businesses alike. In reality, the repair and maintenance of watches are vital to preserving the longevity and accuracy of these intricate mechanisms. It involves meticulous attention to detail, a comprehensive knowledge of various movements, and the ability to restore or replace delicate components.

I strongly believe that as a community we can fight and even reverse this problem by shifting focus. Increasing the number schools for watchmaking, and us, the keepers of time, using our platforms to share our beloved craft with the world and more importantly, the next generation. Sharing our craft and guiding those who are interested toward the proper path to become craftsmen themselves is how we best preserve this often called “dying art”.

The Watchmaker Community and The Future

The community of watchmakers is vibrant and interconnected, with professionals sharing knowledge and techniques through online forums, social media, and international conferences. There is a strong sense of camaraderie and mutual respect among watchmakers, whether they are working for large brands or as independent artisans.

Looking ahead, the future of watchmaking appears bright. As technology continues to evolve, so too will the tools and techniques available to watchmakers. However, the essence of watchmaking—the passion for precision, the dedication to craftsmanship, and the ability to create something truly timeless—will remain unchanged.

Ultimately, being a watchmaker in 2024 is about balancing the rich heritage of the craft with the innovations of the modern world. Add to that the responsibility to share the knowledge, the craft, and the priceless tips and best practices passed down to us from the great watchmakers who came before us. It’s a profession that honors the past while embracing the future, creating timepieces that are not just devices for telling time, but works of art and engineering marvels. It is tremendous work to design and produce a wristwatch. The work, however, does not stop at the sale of the watch. We have an on-going responsibility to preserve these precious timepieces/heirlooms, and this task requires not perfection, but excellence and consistency.

About Ricardo

Ricardo Baez Diaz is the owner and founder of RBD Time Solutions, a premier luxury timepiece repair service in NYC. Ricardo’s meticulous craftsmanship and dedication to excellence have earned him a stellar reputation among collectors, dealers, and enthusiasts. His expertise in restoring fine watches to their original glory reflects his dedication to preserving the art and legacy of watchmaking. When he’s not at the workbench, Ricardo enjoys a nice cup of coffee, BMX riding, and spending time with his cat, Alejandro.

Growing up in the Dominican Republic, I had always loved watches. Particularly Chronographs because of all the little sub-dials and all of the information that was presented in this tiny machine. I had no idea how any of it worked or why these watches seemed to work forever, until one day, they just didn’t work… for good.